Agriculture

Polymers at the Core: Peak Efficiency and Reliability for Agricultural Equipment

Enhancing your technology with Engineering Polymer Solutions

The technology used within the agricultural industry has to bear difficult working conditions. Farmers desire equipment that is reliable, durable, safe and capable of operating efficiently in a changing environment.

We collaborate with leading OEM's to build agricultural equipment for crop harvesting by planting, maintenance, and extraction. The kit we support includes but is not limited to Crop Sprayers, Combine Harvesters, Telehandlers, Planting and Seeding Equipment and Grape Harvesters.

We respect how vital equipment performance is for the end user and work with OEM clients on projects to reduce equipment weight while augmenting load-handling capabilities. Enhance operational efficiency, maintain safety standards, and meet sustainability targets. Nylacast is committed to application consultancy and material innovation to support the industry's need to reduce maintenance, minimise downtime, and extend the lifecycle of machinery and equipment.

Industry Solutions

Experience unparalleled technical support in design and material selection, ensuring your agricultural equipment operates at peak efficiency and reliability.

Applications

Rollers

Manufactured from cast Nylon material, our rollers offer high strength, high-load carrying and a smooth operation.

Washers

Manufacturing over 135,000 per annum. Nylacast washers are hard-wearing and lightweight.

Pulleys

Protect ropes and chains with Nylacast pulleys, the low-friction polymer material significantly reduces wear.

Wear Pads

Experts in combating wear, we produce over 1 million wear pads a year. Our engineered approach allows equipment manufactures to work with us to reduce wear points on their unique application.

The low coefficient of friction and high load-carrying properties of Nylube make our wear pads the perfect choice.

Guides & Tracks

Protect your equipment framework and ensure chains are consistently guided with our leading range of custom materials.

Bearings & Spacers

Used extensively in the construction and agricultural industries, our Oilon bearings are self-lubricating and wear-resistant, proven to increase bearing life span by up to 5 times.

Bearings

The ideal bronze bush replacement, made from Nylube our bushes are hard-wearing, corrosion-resistant and lightweight to offer a fit and forget solution.

Hose Clamps

1/7th the weight of steel, our hose clamps are lightweight and corrosion-free. Our bespoke approach allows us to design a hose clamp to your specific layout.

Problems we solve

- Nylube Wear Strips

Case Study: Enhancing Application Performance

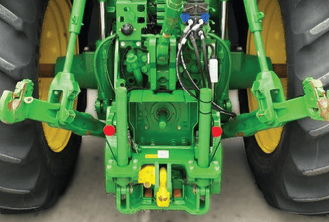

Equipment: Hydraulic Hitch

Industry: Agriculture

Original Material: Acetal

New Material: Nylacast Nylube

Challenge:

Excessive wear, frequent maintenance or replacement of wear strips, and substantial expense and downtime.

Solution:

Nylacast’s wax-filled, self-lubricating, high-performance polymer. Proven to maintain excellent physical properties under stress, providing significantly enhanced wear resistance.

Following field tests in application, Nylacast Nylube wear strips have been deployed, as the standard within all Hydraulic Hitches across Europe and the USA for one of our key customers.

Advantages:

- Low Friction Material

- Increased Wear Life

- Reduced Maintenance

Contact Our Experts

-2.png?width=300&name=Untitled%20design%20(1)-2.png)