Construction

Versatile products with safety & efficiency in mind

Building trust and confidence in your technology performance for your clients

We work with many leading OEMs building construction equipment for off-highway and industrial use. The technology we support includes but is not limited to include: earthmoving, aerial work platforms, material handling, and lifting.

We appreciate how critical construction technology performance is for the end user and work with OEM clients on projects to reduce equipment weight while augmenting load-handling capabilities. Enhance operational efficiency, maintain safety standards, and meet sustainability targets. Nylacast is committed to application consultancy and material innovation to support the industry's need to reduce maintenance, minimise downtime, and extend the lifecycle of machinery and equipment.

In the construction industry, the reduction of equipment weight, while augmenting load handling capabilities, is crucial for enhancing operational efficiency and meeting sustainability targets. Nylacast's commitment to material innovation leads to reduced maintenance needs, minimising downtime, and extending the lifecycle of machinery and equipment.

Industry Solutions

Our solutions bring a unique combination of technical expertise and material innovation to your construction projects, delivering unparalleled value and performance.

Common Applications Supplied

Hose Clamps

1/7th the weight of steel, our hose clamps are lightweight and corrosion-free. Our bespoke approach allows us to design a hose clamp to your specific layout.

Wear Pads

Experts in combating wear, we produce over 1 million wear pads a year. Our engineered approach allows equipment manufactures to work with us to reduce wear points on their unique application.

The low coefficient of friction and high load-carrying properties of Nylube make our wear pads the perfect choice.

Guides & Tracks

Protect your equipment framework and ensure chains are consistently guided with our leading range of custom materials.

Bearings

The ideal bronze bush replacement, made from Nylube our bushes are hard-wearing, corrosion-resistant and lightweight to offer a fit and forget solution.

Problems we solve

- Boom Wear Pads

- PE500 vs Nylacast Big Foot®

Case Study: Enhancing Application Performance

Equipment: Telescopic Handler

Industry: Construction

Original Material: Polyethylene

New Material: Nylacast Nylube Wear Pad

Challenge:

Excessive wear, elevated levels of frequent maintenance and the frequent need for pad replacements

Solution:

Nylacast Nylube, a self-lubricating solution. Its remarkable attributes of, low coefficient of friction, high compressive strength, and outstanding wear resistance enhanced cost efficiency whilst minimizing the input force needed to overcome system friction.

Nylube also exhibits excellent compatibility with various lubricants and operating conditions.

Advantages:

- Low Friction

- Increased Wear Life

- Reduced Maintenance

- Reduced component weight

- Increased Safety

Case Study: Enhancing Application Performance

Equipment: Cranes, Ariel Work Platforms & Telehandlers

Industry: Lifting Solutions

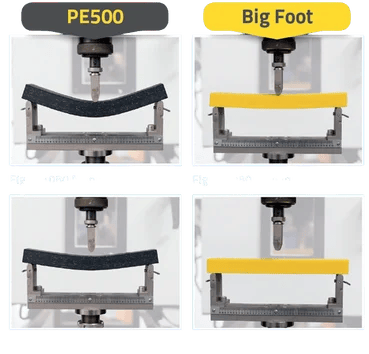

Original Application: Polyethylene - PE 500

New Application: Nylacast Big Foot®

Challenge:

Ensuring secure and stable operations using a reliable, sturdy, and safe crane outrigger pad crafted from a durable material.

A material solution that not only possesses the strength to withstand heavy loads, outperforms alternative methods, but also maintains a lightweight design for easy maneuverability by users.

Solution:

Nylacast Big Foot®, developed with safety, strength, and material recovery in mind.

Nylacast’s Big Foot material exhibits rapid recovery with substantially less deformation than a PE version when force is applied across the pad's surface.

Additionally, the Nylacast outrigger pad requires 3.8 times more load to flex to the same condition as the compared material.

Advantages:

- Manufactured from Premium Cast Nylon Material, site proven to last over 15 years

- Elimination of damage to ground surfaces

- Lightweight, easy to transport/ position handles

- Resistant to corrosion, strong & hard wearing

- Improved replacement for PE crane mats and wood

Contact Our Experts

-2.png?width=300&name=Untitled%20design%20(1)-2.png)