Pipeline Engineering

A dynamic, innovative engineering & supply company offering bespoke & standard products to Oil, Gas & Energy Markets

Pipeline Engineering, a Nylacast company, is a market leading global provider of products, services and engineered solutions for the pipeline pigging and flow assurance industry. We have particular expertise in the design and manufacture of pipeline pigs, which are engineered to meet the specific requirements of individual pipelines.

Uni-cast Polyurethane Pigs

Uni Cast Pigs are produced from our high grade all-polyurethane formulation which gives them excellent chemical and abrasion resistance.

Typically, Uni Cast Pigs are used as sealing pigs to remove debris and to keep pipelines clear of deposit build-up. Uni Cast Pigs are also used for batching operations. They do not require maintenance and are designed to be disposable, making them the preferred type of pig when metal bodied pigs are unsuitable.

The flexibility of our Uni Cast Pigs makes them ideal for use in complex pipeline geometries and small diameter pipelines, typically found in process plants.

Applications

- Product removal

- Batching

- Hydrostatic testing

- Debris removal

- Displacement

- Commissioning / Decommissioning

Sizes Available

- Uni cast pigs are supplied for pipeline sizes ranging from 2” to 14” and larger where required

Density

- Depending upon operational parameters Solid Cast Pigs are supplied as 65A to 75A shore hardness.

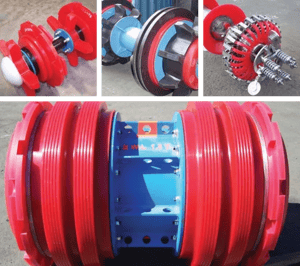

Metal Bodied Pigs

A market leader in the design and manufacture of metal bodied pigs, with our expertise having been gained over many years of operating in the Oil and Gas sector.

In-house expertise means that we can produce metal bodied pigs to meet the specific requirements of pipelines where they will be used. This is achieved by designing these

Metal Bodied Pigs with a combination of components including Cups, Discs, Brushes, Plough Blades, Gauge Plates, Magnets and Tracking Equipment.

Our Metal Bodied pigs are used during all phases of a pipeline life cycle

- Pre-commissioning

- Commissioning

- Production

- Decommissioning

Metal Bodied Pigs - Types

- Uni-directional Standard Cup Pigs

- Uni-directional Conical Cup Pigs

- Bi-directional Disc Pigs

- Cleaning Pigs

- Batching / Separation Pigs Gauging Pigs

Sizes Available

- Metal Bodied Pigs are available for pipelines ranging from 6” - 60”

- Other sizes are available on request

How do we add value

To offer the most appropriate pipeline pigs, a detailed understanding of the variables and factors that affect pigging tool performance is essential. Pipeline Engineering provides comprehensive services related to all aspects of pipeline management and integrity. We provide a range of services to support pipeline pigging operations, this includes management and implementation of all types of pipeline pigging, from simple operational pigging, right through to complex bespoke progressive pigging campaigns. Our expertise in pipeline services and pigging services assures clients that they are receiving the best.

Focused on Operational Excellence. (Service/ HSE/ Quality/ Design/ Manufacture)

A team of service engineers, certified for onshore and offshore operations are available to support or manage pipeline pigging and flow assurance projects. These engineering and project support services are available worldwide.

Pipeline Engineering places safety at the forefront of all our activities. We are also certified to ISO 14001:2015 Environmental standard.

All products are designed and manufactured in line with ISO 9001:2015 and ISO/TS 29001:2011, the Oil & Gas Industry’s Quality Management standard. Product components are extensively tested during manufacture to ensure material consistency and performance.

A team of design engineers work very closely with clients to ensure we develop and provide the most appropriate pipeline pigs for the service that they are required to perform.

Our full range of pipeline pigs are manufactured at our U.K. manufacturing centre which includes ‘state of the art’ computer controlled rapid moulding machines, mixing and dispensing machines and tooling equipment.

Specialty Pigs

We design and build specialty pigs to meet the specific pigging requirements of complex and demanding pipelines. This is achieved through analysis of the existing pipeline issues including assessment of all pipeline features.

Using this information we design, prototype, test and produce bespoke pigs for specific pipeline pigging requirements.

Using specialist pigs developed this way enables innovative and highly effective solutions to be provided, as well as ensuring safe and efficient passage of the pig through a pipeline.

Computer Aided Design

- State of the art 3D CAD design capability allows us to initially develop specialty pigs and simulate their functionality.

Pig Development and Testing

- Specialty pigs are routinely tested in our purpose built test loops. This process allows analysis of performance against the predetermined criteria. It also allows further design refinement to be implemented to benefit specialty pig performance when in fully operational conditions.

Specialty Pig Manufacture / Assembly

- On completion of successful trials, specialty pig designs are transferred to our computer aided manufacturing system for production and assembly.

Specialty Pigs - Types

- Multi-diameter Pigs

- Articulated Pigs

- Isolation Pigs

- High Friction Pigs

- Descaling / Dewaxing Pigs

- Powder Removal Pigs

- Extended Length Pigs

- Bespoke Operational Pigs