Manufacturing Capabilities

Our manufacturing centres are fully equipped to meet your project needs. Our in-house capabilities, supported by our off-machine programming department, produce a range of polymer materials, complemented by our extensive range of CNC cutting, milling, and turning technology.

Our global facilities adhere and operate to ISO 9001:2015 processes, guaranteeing the delivery of a high-quality product to our customers.

Material Production

PA6C Casting Capabilities

- Nylon Tube: Over 20,000 combinations, diameters from 50mm to 1500mm. Various lengths from 330mm to 1220mm are available (subject to size)

- Nylon Rod: Solid rod available from 10mm to 500mm in various lengths from 500mm to 3000mm (subject to diameters).

- Nylon Plate: Plate thickness from 8mm to 120mm available in standard plate sizes of 2000 x 1000mm, 2440 x 1220mm, and 3000 x 1220mm.

.webp?width=345&height=427&name=casting%20on%20manufac%20capab%20page%20(1).webp)

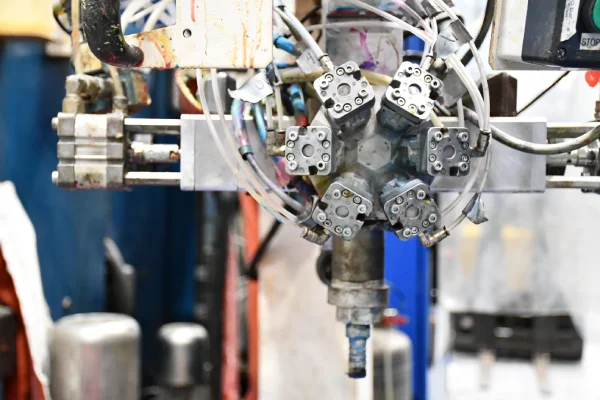

Polyurethane (PU) Casting Capabilities

Our Polyurethane division offers multiple grades in a wide range of custom specifications, from as small as 100 grams to as large as 50 kilograms.

Capabilities:

Are limited by product weight and dimensions relative to:

- Size

- Weight

.webp)

Custom Cast:

Cast Nylon Custom Cast Capabilities

We provide a cast nylon custom casting service for unique profiles. The in-house technical and fabrication team can design and build a tool for uniquely specified products, this leads to a significant increase in efficiency and minimisation of waste, a testament to our ESG responsibility and commitment.

Custom Casing

We have the capability to manufacture products in a wide range of volumes, from small to large, with the capacity to cast up to 300mm in outside diameter. Our expertise extends to creating complex and unique shapes, enhancing product efficiency.

Benefits:

- Reduced waste material

- Reduced machining time

- Decreased cost implications

- Ability to modify material for castings

Custom sizes and shapes in various grades are available subject to drawing and design specifications and customer requirements.

CNC Cut to Size

We have a range of cutting technology, that includes:

- Saw’s:

- Beam Saw for cutting of plates, with a cutting tolerance band of 0.00 +2.00 mm.

- Circular Saw for precise cutting of rods, tubes and blocks to a tolerance of 0.00 +3.00 mm

- Band saw capacity is Ø1100

- 2-Side Rotary Planner: used on plates that require specific tolerance factor of 0 to +0.4 mm

- 4-Side Planner: Angular 4-sided planing for customer specifications that require specific tolerance factor on all faces

Machining

Our machining centre is staffed with skilled professionals and apprentices, manufactures applications in various materials of countless sizes and volumes. We utilise both CNC turning & milling technology, supported with advanced tooling for efficient prototypes and batch quantities production. Our ISO 9001:2015 qualified processes ensure our customers receive a quality product, whether short lead times or scheduled orders are required.

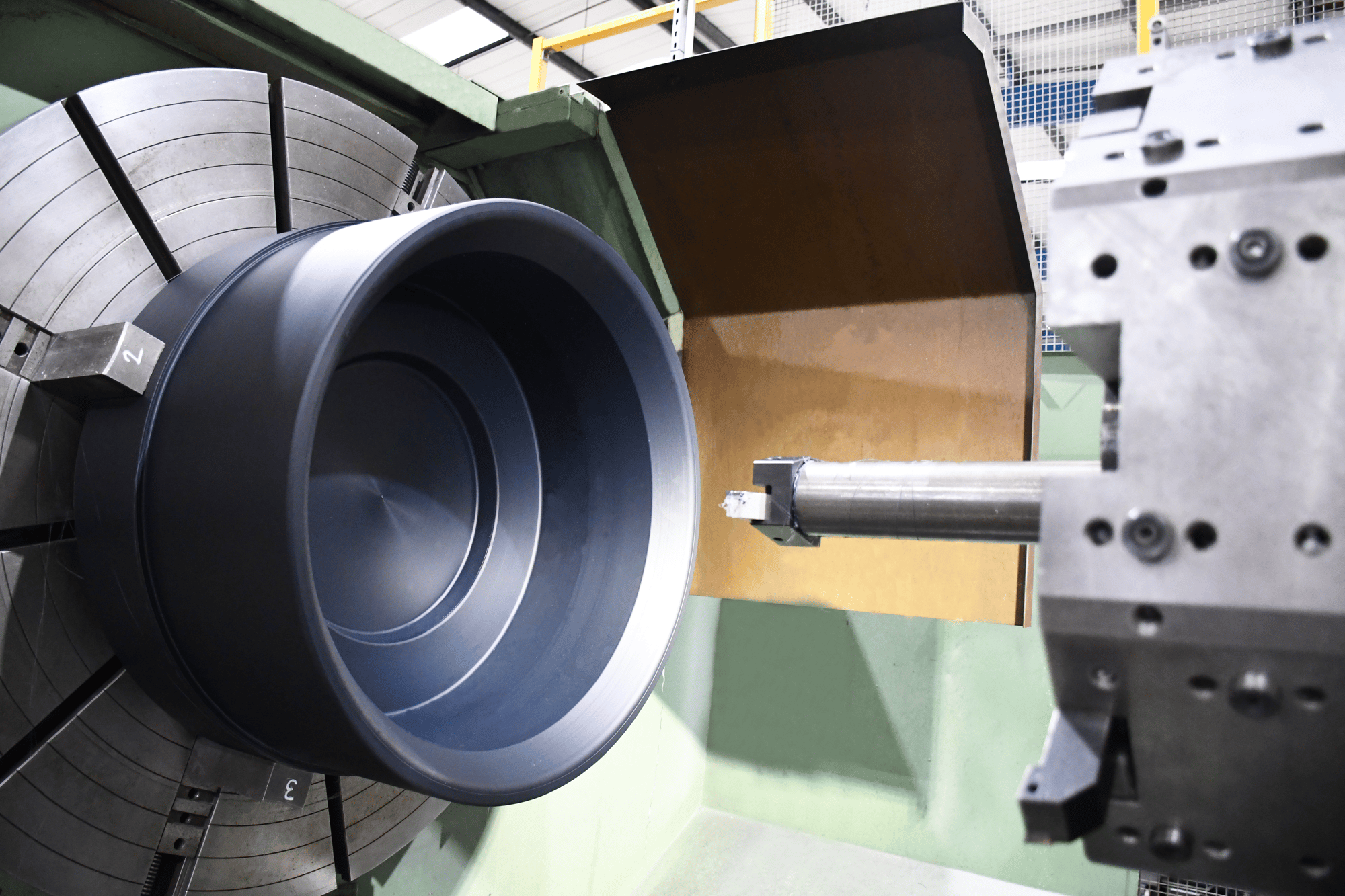

CNC Turning

- Capabilities: Includes 24 CNC Lathes, live tooling, and milling capabilities up to a Max working envelope of Ø2000mm x 1600mm L

- Max Turning Capacity: Up to Ø2000mm x 1200mm L

- Versatility: From single prototypes to high-volume batch orders in the 1000’s.

- Efficiency: Quick lead times, from 1 week* to monthly scheduled orders and stock holding, off-machine programming, and design services available

CNC Milling

-

Capabilities: Includes over 40 CNC Milling Machines of 3, 4, and 5 axes, with a max working envelope up to 3700mm L x 810mm W x 922mm H.

-

Max Milling Capacity: 5 axis machines with a max working envelope Ø2000mm x 1200mm H and 4000MM L x 2000mm W x 931mm H.

-

Versatility: Our dedicated high-volume production quantities vary from 1 off prototypes to batches of 10’s of thousands of parts.

-

Efficiency: Quick lead times, from 1 week* to monthly scheduled orders and stock holding, off-machine programming, and design services available.